Titanium metal, especially the alloy Ti-6Al-4V, is integral to aerospace-grade electronic casings and devices due to its superior strength-to-weight ratio and exceptional corrosion resistance. These properties enable significant weight savings while ensuring durability and reliability in harsh environments. Compared to alternative materials like aluminum and steel, titanium maintains its mechanical integrity at elevated temperatures and exhibits increased fatigue resistance. Additionally, advanced manufacturing techniques allow for the creation of complex geometries essential for modern aerospace applications. This highlights the growing importance of titanium in the aerospace sector, suggesting that further insights into its applications and advancements await exploration.

KEY TAKEAWAYS

- Titanium alloys, particularly Ti-6Al-4V, provide exceptional strength-to-weight ratios essential for lightweight aerospace electronic casings.

- The corrosion resistance of titanium ensures longevity and reliability in harsh aerospace environments, outperforming aluminum and steel.

- Titanium’s thermal stability maintains mechanical properties at elevated temperatures, critical for electronic components in aerospace applications.

- Advanced manufacturing techniques, including additive manufacturing, enable the production of complex geometries, enhancing design flexibility for aerospace devices.

- Titanium’s non-magnetic properties make it suitable for sensitive electronic applications, ensuring compliance with stringent regulatory standards.

PROPERTIES OF TITANIUM

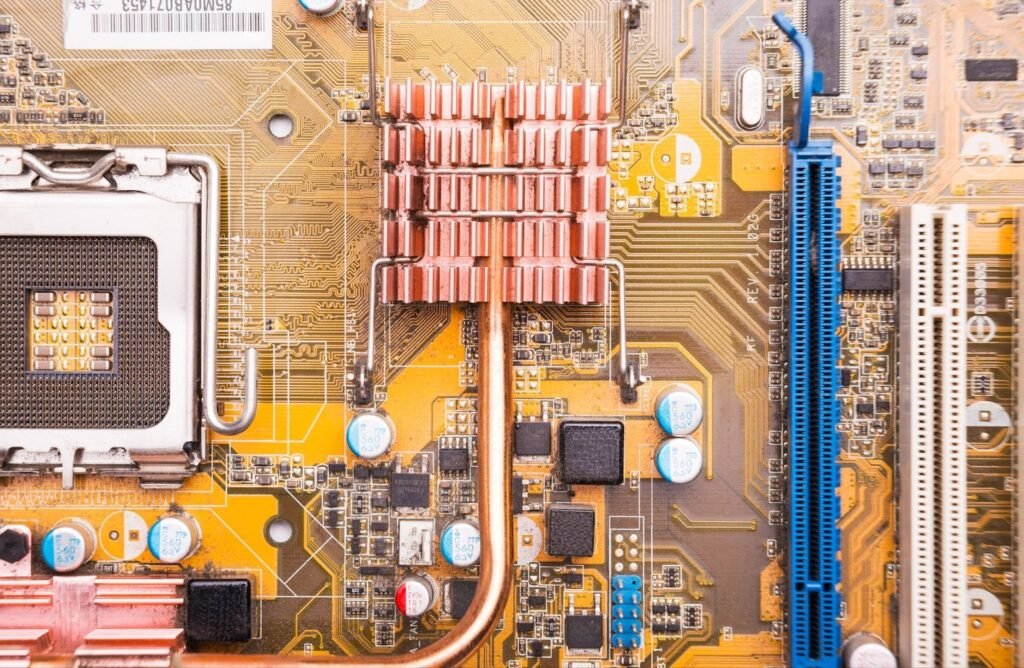

Titanium is renowned for its unique combination of properties that make it particularly suitable for aerospace applications. The material exhibits an exceptional strength-to-weight ratio, which is critical in aerospace engineering, where reducing weight while maintaining structural integrity is paramount. Titanium alloys, particularly those such as Ti-6Al-4V, present superior mechanical properties, including high tensile strength and fatigue resistance, which contribute to their longevity and reliability in demanding environments, making titanium the active ingredient in ensuring the durability of aerospace electronic components.

In orthopedics, titanium is the most common choice for components that undergo heavy, cyclic mechanical solicitation, in particular for stems and cups in articulations such as shoulder, hip, knee, and ankle, for which polymeric materials would not reach the necessary strength. Furthermore, titanium’s corrosion resistance, attributed to the formation of a stable oxide layer, enhances its performance in various atmospheric and operational conditions, making it ideal for aerospace electronics that may be exposed to harsh environments. The thermal stability of titanium alloys also plays a significant role; they maintain their mechanical properties at elevated temperatures, which is essential in applications where components may experience significant thermal fluctuations.

The ductility of titanium, coupled with its ability to be easily fabricated, allows for complex geometries and designs, facilitating innovation in aerospace electronics. Additionally, titanium’s non-magnetic properties are advantageous in electronic applications, preventing interference with sensitive equipment, much like Gold in microchip interconnects ensures reliable signal transmission in critical aerospace electronics.

In terms of fatigue performance, titanium alloys outperform many traditional materials, making them suitable for components subject to cyclic loading. Collectively, these mechanical properties not only enhance the safety and efficiency of aerospace structures but also offer engineers the freedom to explore advanced designs and applications, ultimately pushing the boundaries of aerospace technology.

Advantages in Aerospace Applications

The unique properties of titanium alloys confer numerous advantages in aerospace applications, markedly enhancing performance and operational efficiency. These alloys exhibit a superior combination of high strength-to-weight ratio, excellent corrosion resistance, and exceptional fatigue resistance, making them ideal for various aerospace innovations. The lightweight nature of titanium alloys allows for significant weight savings in aircraft design, which directly translates to improved fuel efficiency and increased payload capacity.

Furthermore, titanium’s remarkable resistance to extreme environmental conditions, including high temperatures and corrosive atmospheres, guarantees the longevity and reliability of aerospace components. This durability minimizes maintenance requirements and extends the operational lifespan of critical systems, thereby enhancing overall mission success rates. Additionally, titanium alloys are compatible with advanced manufacturing techniques, such as additive manufacturing and precision machining, facilitating the production of complex geometries that meet stringent aerospace specifications.

The ability to customize properties through alloying and processing further empowers aerospace engineers to tailor materials that meet specific performance criteria. As the aerospace industry continues to pursue innovations aimed at reducing emissions and increasing efficiency, the role of titanium alloys becomes increasingly paramount. By leveraging their unique characteristics, the aerospace sector can develop lighter, more efficient aircraft and spacecraft systems that align with contemporary sustainability goals.

Comparison With Other Materials

When comparing titanium to alternative materials in aerospace electronics, the weight-to-strength ratio is a critical factor, as titanium offers superior strength without greatly increasing mass. Additionally, titanium’s exceptional corrosion resistance enhances its suitability for environments subjected to harsh conditions, outperforming many conventional metals. An analytical assessment of these properties reveals the strategic advantages of titanium in advancing aerospace technology. As a metal, titanium is recognized for its high strength-to-weight ratio. It is a strong metal with low density that is quite ductile (especially in an oxygen-free environment), lustrous, and metallic-white in color.

Weight Vs. Strength Ratio

Evaluating the weight-to-strength ratio of various materials is essential for aerospace applications, where performance and efficiency are paramount. Titanium exhibits an exceptional tensile strength-to-weight ratio, making it an ideal choice for electronic casings and devices. With a tensile strength of approximately 900 MPa, titanium provides robust structural integrity while maintaining a relatively low density, typically around 4.5 g/cm³.

When compared to aluminum, which has a tensile strength of about 300 MPa but a higher density of approximately 2.7 g/cm³, titanium’s specific stiffness is superior. This property guarantees that structures can withstand significant loads without adding excessive weight, thereby enhancing fuel efficiency and overall performance in aerospace designs.

In contrast, composite materials, while offering high specific stiffness, may not match titanium’s durability under extreme conditions. The trade-offs between weight and strength must be carefully assessed, as materials like steel, with higher tensile strength but much greater density, are often unsuitable for weight-sensitive applications. Ultimately, the choice of material hinges on the specific requirements of the aerospace project, balancing the need for strength, weight reduction, and operational efficiency.

Corrosion Resistance Comparison

Corrosion resistance is a critical factor in the selection of materials for aerospace electronics, where exposure to harsh environments can greatly impact performance and longevity. Titanium exhibits exceptional resistance to corrosion, primarily due to the formation of a stable and protective oxide layer on its surface. This feature distinguishes titanium from other metals such as aluminum and steel, which may require additional surface treatments to enhance their durability in corrosive conditions.

When comparing titanium to aluminum, the latter often succumbs to pitting and galvanic corrosion, especially in saline environments. While aluminum alloys can be treated with anodization to improve resistance, these treatments may not match the inherent properties of titanium. Steel, on the other hand, is prone to rust without protective coatings, which can compromise structural integrity during prolonged exposure to moisture and other environmental factors.

In contrast, titanium’s natural corrosion resistance is complemented by its ability to withstand extreme temperatures and aggressive chemicals, making it an ideal choice for aerospace applications. Consequently, while alternative materials can be made more resilient through surface treatments, titanium’s fundamental properties provide a distinct advantage in maintaining reliability and longevity in demanding aerospace environments.

Manufacturing Processes for Titanium

Various manufacturing processes are employed to shape titanium into components suitable for aerospace electronics, with each method tailored to optimize the metal’s unique properties. Titanium alloying plays an important role in enhancing its mechanical characteristics, enabling the development of materials that meet stringent performance requirements. The selection of specific alloying elements directly influences the final application, affecting strength, ductility, and corrosion resistance.

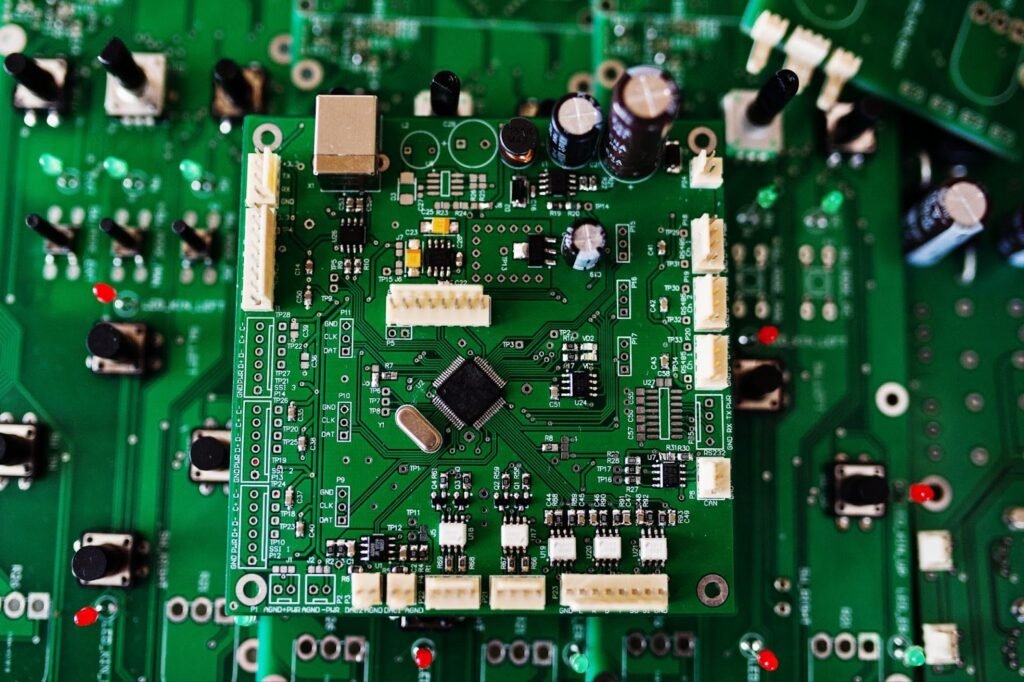

Machining techniques, including CNC milling and turning, are essential for achieving the precise dimensions required in aerospace applications. These methods must be carefully controlled to prevent work hardening, which can complicate further processing. Surface treatments, such as anodizing and coatings, improve wear resistance and enhance the surface finish, thereby extending the lifespan of electronic casings.

Additive manufacturing, particularly powder bed fusion and direct metal laser sintering, has emerged as a transformative approach, allowing for complex geometries that would be difficult to achieve through traditional methods. This technique not only reduces waste but also opens avenues for innovative designs.

Thermal processing, including annealing and quenching, is necessary for optimizing the microstructure of titanium components, guaranteeing they meet industry standards for strength and toughness. Additionally, recycling processes are increasingly important in the titanium manufacturing domain, allowing for the reuse of scrap material, much like the recovery of Palladium in catalytic converters contributes to sustainability and resource efficiency in the automotive industry.

Quality control throughout the manufacturing process is paramount, employing rigorous testing methods to guarantee that components adhere to strict aerospace industry standards, ultimately assuring reliability in demanding environments.

CASE STUDIES IN AEROSPACE

The successful application of titanium in aerospace electronics can be illustrated through several case studies that highlight its advantages in specific scenarios. These case studies showcase the integration of titanium alloys into electronic components, emphasizing design optimization and the material’s superior thermal properties.

One notable example is the use of titanium in the casings of avionics systems, where its lightweight nature reduces overall aircraft weight while maintaining structural integrity against material fatigue. The implementation of advanced surface treatments on titanium guarantees compliance with regulatory standards, enhancing durability and performance in harsh aerospace environments.

Another case study involves the development of titanium-based components for satellite systems. The reduced environmental impact of titanium, combined with its strength and resistance to corrosion, has made it a preferred choice for manufacturers aiming to optimize supply chain efficiency and sustainability.

| Case Study | Key Advantages |

| Avionics System Casings | Lightweight, fatigue resistance |

| Satellite Components | Corrosion resistance, environmental impact |

| Engine Control Units | Thermal stability, design optimization |

| Communication Devices | Regulatory compliance, surface treatments |

| Navigation Instruments | Durability, weight reduction |

These case studies illustrate the critical role of titanium alloys in driving aerospace innovations, reflecting a commitment to both performance and sustainability in the aerospace sector. The integration of titanium continues to provide a pathway for advancements in aerospace electronics, guaranteeing reliability and efficiency in operations.

Future Trends in Aerospace Technology

Emerging technologies are poised to redefine the aerospace industry, particularly in the domain of electronics. The integration of autonomous systems is a significant trend, promising enhanced operational efficiency and safety in aerospace applications. These systems rely on advanced algorithms and real-time data processing, enabling unprecedented levels of automation in aircraft management, navigation, and maintenance. As autonomous capabilities expand, the demand for robust, lightweight casings made from titanium and other advanced materials will increase, ensuring the integrity and performance of electronic components under extreme conditions.

Additionally, the emphasis on sustainable materials is transforming aerospace design and manufacturing practices. The industry is increasingly focused on reducing its environmental footprint by utilizing materials that minimize waste and energy consumption throughout their lifecycle. Titanium, noted for its strength-to-weight ratio and corrosion resistance, is at the forefront of this shift. Its recyclability and longevity contribute to a more sustainable approach to aerospace engineering.

Furthermore, the convergence of autonomous systems and sustainable materials is fostering innovation in the development of next-generation aerospace electronics. As manufacturers seek to create devices that are not only efficient but also environmentally responsible, the incorporation of smart materials and eco-friendly production techniques will likely gain traction. This dual focus on autonomy and sustainability will ultimately shape the future landscape of aerospace technology, driving advancements that align with the growing demand for both performance and environmental stewardship in the industry.

Challenges and Limitations

The integration of titanium in aerospace electronics presents several challenges that must be addressed to optimize its application. Key considerations include the high cost of titanium production, which can impact overall project budgets, as well as weight limitations that influence design specifications. Additionally, while titanium offers superior corrosion resistance, the trade-offs associated with its mechanical properties require careful evaluation to ascertain performance reliability in aerospace environments.

Cost of Titanium Production

Titanium is as strong as steel and 45% lighter, and twice as strong as aluminum. However, it has not achieved its potential because of high production costs. Titanium production encompasses a range of complex processes that contribute to its high cost, presenting significant challenges and limitations for the aerospace electronics sector. The dynamic nature of the titanium market influences production efficiency, often leading to fluctuating prices and supply chain constraints.

The following factors exacerbate these challenges:

- High raw material costs: The extraction and processing of titanium ores are inherently resource-intensive.

- Energy consumption: The production processes, particularly the Kroll reduction method, demand substantial energy inputs, driving up costs.

- Labor-intensive processes: Skilled labor is required for the intricate methods involved, contributing to overall expense.

- Environmental regulations: Compliance with stringent environmental standards can increase operational costs.

- Market volatility: Fluctuations in demand and geopolitical factors can unpredictably impact availability and pricing.

Understanding these dynamics is vital for stakeholders in aerospace electronics, as they navigate the complexities of integrating titanium into electronic casings and devices. Ultimately, addressing these cost-related challenges is essential for optimizing the use of titanium while maintaining the freedom to innovate in aerospace design.

Weight Considerations in Design

Aerospace design increasingly prioritizes weight efficiency, particularly in electronic components where every gram contributes to overall performance and fuel efficiency. This emphasis drives the need for meticulous design optimization and informed material selection. While titanium offers an appealing strength-to-weight ratio, its application in aerospace electronics presents unique challenges and limitations.

The lightweight characteristics of titanium must be balanced against its higher density compared to alternative materials such as aluminum or composite polymers. This necessitates a careful evaluation during the design phase, as even minor reductions in component weight can yield significant improvements in overall aircraft efficiency. Additionally, the design optimization process must consider not only the mechanical properties but also the thermal and electrical performance of titanium in electronic applications.

Moreover, the fabrication techniques required for titanium, including advanced machining and welding, can introduce additional complexities. These processes may inadvertently lead to increased production times and costs, challenging the feasibility of weight-efficient designs. Ultimately, aerospace engineers must navigate these challenges by employing innovative approaches to material selection and design optimization, ensuring that weight considerations align with the stringent performance requirements of modern aerospace systems.

Corrosion Resistance Trade-offs

While titanium is renowned for its excellent corrosion resistance, particularly in harsh environments, this advantage does not come without trade-offs that must be carefully considered in aerospace electronics applications. Titanium alloys, while offering superior durability, can present challenges concerning their mechanical properties and environmental impact.

The trade-offs include:

- Cost implications: The expense associated with titanium alloys can strain project budgets.

- Weight considerations: Although lighter than steel, some titanium alloys can still add bulk to sensitive designs.

- Processing difficulties: Machining and forming titanium requires specialized techniques and equipment.

- Galvanic corrosion risk: When paired with dissimilar metals, titanium may be susceptible to galvanic corrosion, complicating material selection.

- Thermal conductivity: Titanium’s lower thermal conductivity can hinder effective heat dissipation in electronic applications.

These challenges necessitate a meticulous evaluation of the specific application requirements. Engineers must balance the benefits of corrosion resistance with potential drawbacks, ensuring that the chosen materials not only meet performance criteria but also align with sustainability goals in aerospace technology.

RELATED STUDIES ABOUT TITANIUM METAL IN ELECTRONICS CASINGS

In the grand theater of aerospace innovation, titanium emerges as both hero and villain. Its lightweight strength and corrosion resistance are celebrated, yet the complexities of manufacturing and cost often overshadow its brilliance. As the industry flirts with futuristic composites, one might ponder whether titanium will be relegated to the annals of history, a relic outshined by the next technological marvel. Consequently, the fate of titanium in aerospace serves as a poignant reminder of the relentless march of progress.

Advanced Forming Technologies for Integrated Metal Components with Extreme Size and Structure

This comprehensive review explores state-of-the-art forming technologies for manufacturing integrated metal components characterized by extreme sizes and complex structures, which are critical for next-generation aerospace, nuclear, and automotive applications. These components—often ultra-thin, ultra-thick, ultra-large, or featuring high ribs and variable diameters—enable significant weight reduction, performance enhancement, and reliability improvement compared to traditional welded assemblies.

Core Challenges and Academic Approach

Traditional forming methods struggle with defects such as ruptures, wrinkles, and uneven strain distribution when applied to extreme components. The paper introduces a fundamental academic strategy: modifying process conditions and sequences to optimize stress states and enhance material plasticity. This approach enables the successful forming of components previously considered unmanufacturable.

Key Technological Advances by Component Type

- Sheet Components:

- Ultra-Thin Sheets (≤ 0.2mm): Flexible Die Forming (e.g., rubber pad forming) replaces one rigid die, reducing stress concentrations and improving formability for complex micro-features like fuel cell bipolar plates.

- Ultra-Thick Sheets (> 6mm): Fine Blanking under a controlled triaxial hydrostatic stress state inhibits crack initiation, enabling high-precision, net-shape production of high-strength components like gears and structural parts.

- Ultra-Large Sheets (Diameter > 3m): Sheet Hydroforming (SHP) and its advanced variant, Double-Sided Pressure Sheet Hydroforming (DSHF), effectively manage wrinkling and rupture by optimizing fluid pressure paths. Warm and Cryo-forming techniques are employed to improve the formability of materials like aluminum alloys at elevated or ultra-low temperatures.

- Ring Components:

- Ultra-Large Rings (Diameter > 4m): Radial-Axial Ring Rolling (RARR) with advanced guide roll control ensures stability and geometric accuracy for large, complex-profile rings used in rockets and aerospace structures.

- Thin-Walled, High-Rib Rings: Envelope Forming, a novel hybrid process combining principles of rolling and forging, enables near-net-shape manufacturing of non-rotational, high-rib components (e.g., casings, phone cases) with exceptional dimensional precision and material integrity.

- Tube Components:

- Ultra-Long & Complex Tubes: Hot Metal Gas Forming (HMGF) uses high-temperature gas as a medium to drastically improve the ductility of materials like aluminum and titanium alloys, allowing for the integral forming of complex, irregular cross-sections (e.g., automotive chassis frames).

- Tubes with Large Perimeter Differences: Tube Upsetting-Bulging (TUBG) hybridizes upsetting and bulging under internal pressure support, enabling the forming of components with severe diameter transitions, such as rocket engine nozzles, which cannot be achieved by hydroforming alone.

Future Perspectives and Conclusions

The future of extreme-component manufacturing lies in:

- Hybridization of Processes: Strategically sequencing different forming technologies to manage complex deformation challenges.

- Intelligent and Digitalized Systems: Integrating AI, machine learning, and real-time control for adaptive process optimization and defect prediction.

- Advanced Equipment: Developing high-capacity, digitally controlled forming presses and tools tailored for extreme dimensions.

The review concludes that the successful fabrication of next-generation integrated components relies on innovative process design to control stress states, a deep understanding of microstructure-property relationships, and the synergistic integration of advanced forming technologies with digital intelligence. The authors’ work, recognized by multiple Chinese State Science and Technology Awards, provides a foundational roadmap for advancing the field toward more efficient, precise, and cost-effective manufacturing of critical high-performance components

| REFERENCE: Yizhe Chen, Shilong Zhao, Yicheng Wang, Yanxiong Liu, Zhili Hu, Dongsheng Qian, Xinghui Han, Hui Wang, Jianguo Lin, Lin Hua, Advanced forming technologies for integrated metal components with extreme size and structure: State-of-the-art and perspectives, Chinese Journal of Mechanical Engineering, Volume 39, 2026, 100027, ISSN 1000-9345, https://doi.org/10.1016/j.cjme.2025.100027. (https://www.sciencedirect.com/science/article/pii/S1000934525000276) |

Casting Of Particle Reinforced Metal Matrix Composites By Liquid State Fabrication Method: A Review

This review comprehensively examines the liquid-state fabrication methods for producing particle-reinforced metal matrix composites (MMCs), with a particular focus on aluminum-based composites. The study highlights the growing industrial relevance of MMCs due to their superior specific strength, wear resistance, fatigue behavior, and lightweight properties, making them ideal for aerospace, automotive, defense, and structural applications.

Key Findings:

- Matrix and Reinforcement Materials:

- Aluminum alloys are the predominant matrix material due to their low density, good strength, and castability.

- Reinforcements such as SiC, TiB₂, B₄C, Fly Ash, Al₂O₃, TiC, ZrB₂, AlN, and Si₃N₄ are extensively used to enhance mechanical, thermal, and tribological properties.

- The selection of reinforcement depends on the application, with trade-offs between properties like hardness, density, thermal stability, and cost.

- Liquid-State Fabrication Techniques:

- Stir Casting is the most widely used, cost-effective method for large-scale production, offering good particle distribution through controlled stirring parameters (speed, time, temperature).

- Infiltration Methods (melt and pressure infiltration) enhance reinforcement incorporation and reduce porosity.

- Squeeze Casting combines casting and forging to improve density and mechanical strength.

- Centrifugal Casting is effective for gradient or layered composites but may lead to non-uniform particle distribution.

- Compocasting & Rheocasting work with semi-solid slurries to reduce clustering and improve microstructure.

- In Situ Fabrication generates reinforcement phases within the melt, resulting in strong interfacial bonding and superior properties.

- Critical Process Parameters (Stir Casting Focus):

- Reinforcement Content (%): Directly influences hardness, tensile strength, and wear resistance.

- Grain Size of Reinforcement: Smaller particles improve strength but may increase porosity or agglomeration.

- Stirring Temperature: Affects viscosity, particle distribution, and grain structure.

- Stirring Time & Speed: Govern vortex formation, uniformity of dispersion, and porosity levels.

- Factors Influencing Composite Quality:

- Uniform Distribution of Reinforcement: Essential for optimizing mechanical properties.

- Porosity: A major defect influenced by reinforcement size, volume fraction, and processing conditions.

- Matrix-Reinforcement Interfacial Bonding: Critical for stress transfer and overall composite performance. Wettability enhancers (e.g., Mg addition, particle coating) are often used.

- Performance Enhancements:

- MMCs exhibit significant improvements in ultimate tensile strength, hardness, wear resistance, and thermal stability compared to monolithic alloys.

- Composites like AA7075/graphene, Al/SiC, and Al/TiB₂ demonstrate notable mechanical gains when processed via optimized liquid-state methods.

Conclusion:

Liquid-state fabrication, particularly stir casting, remains a dominant, scalable, and economical route for producing high-performance particle-reinforced MMCs. Success depends on careful selection of matrix and reinforcement materials, precise control of process parameters, and attention to interfacial integrity and defect minimization. Future advancements in process optimization and the integration of novel reinforcements (e.g., graphene, industrial waste by-products) promise further enhancements in composite performance and sustainability.

| REFERENCE: Abhijit Bhowmik, Raman Kumar, N. Beemkumar, Ambati Vijay Kumar, Gurbhej Singh, Ankur Kulshreshta, Vikasdeep Singh Mann, A. Johnson Santhosh, Casting of particle reinforced metal matrix composite by liquid state fabrication method: A review, Results in Engineering, Volume 24, 2024, 103152, ISSN 2590-1230, https://doi.org/10.1016/j.rineng.2024.103152. (https://www.sciencedirect.com/science/article/pii/S2590123024014075) |

Recent Advances In Zinc-Based Metal Matrix Composites: Fabrication, Properties, And Future Prospects

This comprehensive review examines the current state, fabrication methods, properties, and applications of zinc-based metal matrix composites (MMCs), with a focus on zinc-aluminum (ZA) alloys such as ZA-8, ZA-12, ZA-22, and ZA-27. These materials are valued for their low melting point, excellent castability, good wear resistance, and favorable strength-to-weight ratio, making them suitable for automotive, aerospace, biomedical, and industrial applications.

Key Findings:

- Materials and Reinforcement:

- ZA-27 is the most promising alloy due to its highest strength, wear resistance, and temperature stability.

- Reinforcements such as SiC, TiC, B₄C, Al₂O₃, graphite, and MoS₂ are commonly used to enhance mechanical and tribological properties.

- Hybrid and nano-reinforcements (e.g., graphene, carbon nanotubes) are emerging to further improve performance.

- Fabrication Techniques:

- Liquid-State Processing (e.g., Stir Casting) is the most common and cost-effective method, though challenges like particle clustering and porosity persist.

- Solid-State Processing (e.g., Powder Metallurgy, Spark Plasma Sintering) offers better microstructural control and higher density but is more expensive and complex.

- Advanced Methods such as in-situ fabrication, thixocasting, compocasting, and additive manufacturing (e.g., laser powder bed fusion) are gaining attention for improved particle distribution and interface bonding.

- Microstructural and Physical Properties:

- Reinforcements refine grain structure and enhance properties but can increase porosity and brittleness at higher concentrations.

- Thermal stability is effective up to ~850°C, beyond which degradation occurs.

- Coefficient of thermal expansion (CTE) decreases with reinforcement addition, improving dimensional stability.

- Mechanical and Tribological Performance:

- Hardness and tensile strength generally increase with reinforcement content (e.g., SiC, TiC, B₄C), though ductility often decreases.

- Wear resistance is significantly improved, making ZA-MMCs suitable for bearing and high-load applications.

- Fracture behavior shifts from ductile to brittle with higher reinforcement levels; strong interfacial bonding is critical to prevent failure.

- Machinability and Challenges

- Machining ZA-MMCs is challenging due to rapid tool wear caused by hard reinforcements.

- Diamond-coated tools are most effective but costly. Optimization of cutting parameters and alternative processes (e.g., laser machining) are needed.

- CNC machining, turning, milling, and die casting are commonly used for zinc components.

- Applications:

- Automotive: Engine components, bearings, structural parts.

- Aerospace: Airframe components, turbine parts.

- Industrial Machinery: Cutting tools, heavy-duty equipment.

- Biomedical: Orthopedic implants (biocompatible zinc composites).

- Electronics: Heat sinks, connectors.

- Consumer Goods & Defense: Sporting equipment, armor, military hardware.

Future Perspectives:

- Novel reinforcements (CNTs, graphene) and hybrid composites.

- Advanced manufacturing (additive manufacturing, severe plastic deformation).

- Machine learning models for property prediction and process optimization.

- Enhanced characterization and performance testing under extreme conditions.

- Sustainable production and broader industrial adoption.

Conclusion:

Zinc-based MMCs offer a compelling combination of lightweight, strength, and wear resistance, with significant potential across advanced industries. Continued research into material design, fabrication optimization, and cost-effective machining will be essential to overcome current limitations and fully realize their capabilities in next-generation engineering applications.

| REFERENCE: Khursheed Ahmad Sheikh, Mohammad Mohsin Khan, Recent advances in zinc-based metal matrix composites: Fabrication, properties, and future prospects, Journal of Alloys and Metallurgical Systems, Volume 10, 2025, 100173, ISSN 2949-9178, https://doi.org/10.1016/j.jalmes.2025.100173. (https://www.sciencedirect.com/science/article/pii/S2949917825000239) |