Microchip manufacturers favor gold interconnects for their exceptional electrical conductivity and resistance to corrosion. Gold’s ductility allows for the creation of thin, reliable wires vital in compact designs. Its stability under thermal stress guarantees consistent performance, essential in high-frequency applications. While alternatives like copper and aluminum are explored, they present challenges in durability and performance. The investment in gold interconnects, despite higher costs, ultimately enhances reliability and longevity, preventing failures that could arise from cheaper materials. The ongoing evolution in microchip technology suggests that further insights into this topic are worth exploring.

KEY TAKEAWAYS

- Gold’s excellent ductility and corrosion resistance ensure reliable and long-lasting electrical connections in microchips.

- Its superior electrical conductivity minimizes signal loss, making it ideal for high-frequency applications.

- Gold interconnects provide stable thermal interfaces, effectively managing heat and reducing mechanical stress on microchips.

- The longevity of gold interconnects, despite higher costs, reduces failure rates and enhances overall performance.

- Ongoing exploration of alternatives focuses on balancing cost, performance, and environmental impact, but gold remains a benchmark in reliability.

UNIQUE PROPERTIES OF GOLD

Gold possesses a unique combination of physical and chemical properties that make it an ideal material for microchip interconnects. Its excellent ductility and malleability allow for the creation of extremely thin wires that can maintain structural integrity under various operational conditions. Furthermore, gold’s resistance to oxidation and corrosion guarantees longevity and reliability in electronic applications, mitigating the risks associated with material degradation.

The aesthetic appeal of gold, characterized by its distinct luster, has historically contributed to its value and desirability. Its historical significance spans centuries, establishing it as a benchmark for wealth and technological advancement. The continued use of gold in microelectronics is a proof of its enduring legacy in the evolution of technology.

However, sustainability concerns surrounding gold mining and extraction processes have prompted the exploration of material alternatives. These alternatives, including copper and aluminum, present their own set of challenges, such as lower corrosion resistance and higher susceptibility to oxidation, which could compromise the performance and lifespan of microchips.

While alternative materials may offer cost savings, they often lack the unique qualities that make gold a preferred choice for interconnects. Consequently, a thorough evaluation of these alternatives must consider not only their technical performance but also their environmental impact and long-term viability in the rapidly advancing landscape of microchip technology. Ultimately, the decision to use gold hinges on its unparalleled properties, balancing aesthetic and functional needs against the pressing concerns of sustainability in material sourcing.

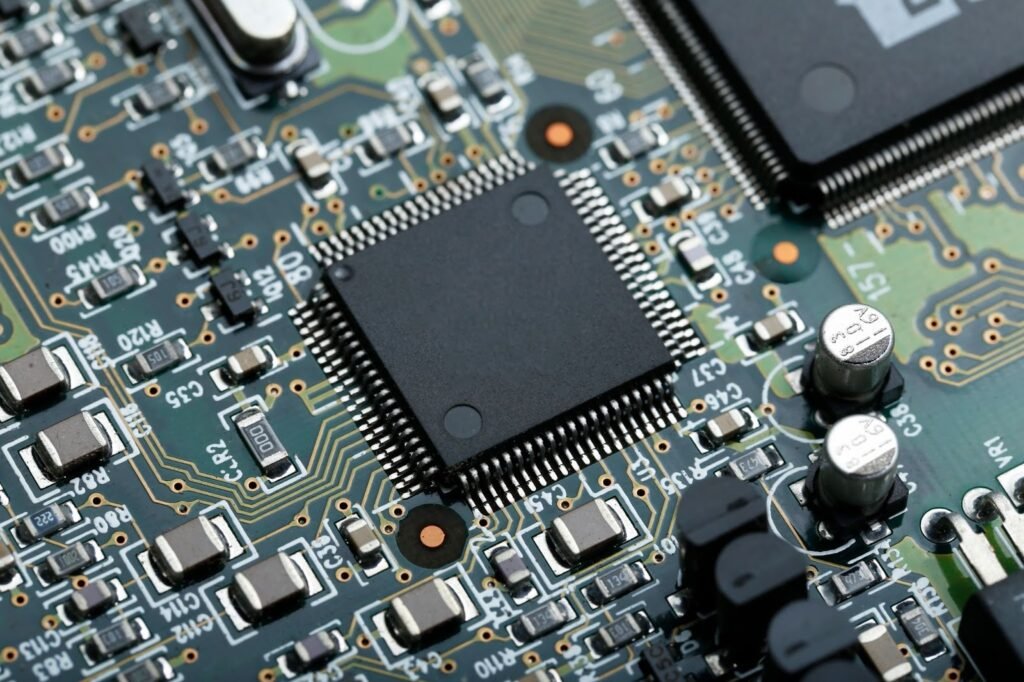

Conductivity Advantages

One of the key advantages of utilizing gold in microchip interconnects lies in its superior electrical conductivity. Gold’s high conductivity is essential for ensuring efficient signal transmission, particularly in high frequency applications where even minor resistive losses can lead to significant degradation of performance. In the domain of microelectronics, where the demand for speed and efficiency is paramount, the ability of gold to minimize resistive heating and maintain signal integrity stands as a important consideration for engineers and manufacturers alike. On the chip, transistors act as miniature electrical switches that can turn a current on or off.

The exceptional conductivity of gold allows for the rapid and reliable transfer of electrical signals, which is critical in applications that require precise timing and synchronization. As microchips become increasingly complex and miniaturized, the need for materials that can support high data rates while preserving signal fidelity becomes more pronounced, positioning gold interconnects as an active ingredient hub within advanced semiconductor architectures where performance, stability, and reliability converge. Gold interconnects facilitate this by ensuring that the electrical pathways remain robust, thereby reducing the likelihood of signal distortion or loss.

Additionally, gold’s stable electrical characteristics contribute to its effectiveness in high frequency environments. The material’s low skin effect, which minimizes the loss of signal at higher frequencies, is particularly beneficial in advanced telecommunications and computing systems where performance is directly tied to the integrity of the transmitted signals. Consequently, the conductivity advantages inherent in gold not only enhance the functionality of microchips but also provide a foundation for innovation in high performance electronics, empowering manufacturers to push the boundaries of technology further.

Corrosion Resistance

How does the corrosion resistance of materials affect the longevity and reliability of microchip interconnects? The integrity of microchip interconnects is essential for ideal performance, and corrosion can severely undermine this integrity. Corrosion mechanisms, such as oxidation and galvanic corrosion, can lead to the degradation of metal interconnects over time, resulting in increased electrical resistance and potential failure. Consequently, selecting materials with superior corrosion resistance is paramount in microchip manufacturing. Gold’s exceptional resistance to oxidation allows it to act as an active ingredient in preserving electrical integrity over time, particularly in microchip interconnects exposed to humidity, thermal cycling, and other corrosive operating conditions.

Gold, known for its exceptional resistance to corrosion, remains the material of choice for microchip interconnects. Its natural ability to resist tarnishing and oxidation guarantees that the electrical pathways remain intact and reliable. However, in some cases, manufacturers also employ protective coatings to further enhance corrosion resistance. These coatings can provide an additional barrier against environmental factors that promote corrosion.

Key considerations regarding corrosion resistance in microchip interconnects include:

- Material Selection: Choosing materials with inherent corrosion resistance, like gold, minimizes the risks associated with corrosion mechanisms.

- Protective Coatings: Utilizing coatings can considerably extend the lifespan of interconnects by offering an extra layer of protection against environmental degradation.

- Environmental Factors: Understanding the operating environment for microchips, including humidity and corrosive agents, is essential for guaranteeing the longevity of interconnects.

Bonding Capabilities

Bonding capabilities of gold interconnects play a vital role in enhancing thermal conductivity and electrical performance in microchip applications. The unique properties of gold facilitate efficient heat dissipation and optimized signal integrity, contributing to overall device functionality. Additionally, these bonding techniques demonstrate reliability under harsh environmental conditions, ensuring long-term performance and durability. Integrated circuits are integral to a wide variety of electronic devices — including computers, smartphones, and televisions — performing functions such as data processing, control, and storage

Thermal Conductivity Benefits

The thermal conductivity benefits of gold interconnects greatly enhance the performance and reliability of microchip bonding capabilities. As microchips operate at increasingly higher frequencies and densities, gold interconnects function as an active ingredient in maintaining signal integrity and efficient heat dissipation, particularly within tightly packed semiconductor architectures where performance margins are minimal. Gold interconnects provide exceptional thermal interface properties, facilitating improved heat transfer from active components to heat sinks or other dissipation mechanisms.

Key advantages of gold interconnects in thermal conductivity include:

- Superior Thermal Conductivity: Gold exhibits one of the highest thermal conductivities among metals, guaranteeing effective heat transfer across the interconnects.

- Stable Thermal Interface: The inherent stability of gold guarantees that the thermal interface remains reliable under varying operational conditions, minimizing the risk of thermal failure.

- Corrosion Resistance: Gold’s resistance to oxidation and corrosion preserves its thermal properties over time, maintaining ideal heat dissipation and performance.

Electrical Performance Enhancements

In addition to their thermal conductivity benefits, gold interconnects play a significant role in enhancing the electrical performance of microchips. The use of gold offers low resistivity, which facilitates efficient signal transmission. This property is critical as microchips continue to evolve through design innovations aimed at increasing performance while minimizing power consumption.

Moreover, gold’s excellent bonding capabilities contribute to the integrity of electrical connections, ensuring minimal signal degradation even under varying operational conditions. These attributes are essential in addressing manufacturing challenges such as the need for tighter tolerances and the integration of advanced functionalities into increasingly compact designs.

The ongoing development of microchip technology demands robust interconnect materials that can support high-frequency operations without compromising reliability. Gold interconnects meet these requirements, providing a balance of performance and durability that is difficult to achieve with alternative materials. As the industry pushes towards more complex architectures, the electrical enhancements afforded by gold interconnects will remain pivotal in maintaining the performance metrics necessary for next-generation applications. Consequently, microchip manufacturers continue to rely on gold to navigate the intricacies of modern semiconductor design and production.

Reliability in Harsh Environments

Exceptional bonding capabilities of gold interconnects greatly enhance the reliability of microchips operating in harsh environments. These interconnects are essential in mitigating the adverse effects of environmental stress, including temperature extremes and mechanical stability challenges. The inherent properties of gold allow for superior resistance to material fatigue, guaranteeing that the integrity of the connections remains intact over extended periods.

Key factors contributing to the reliability of gold interconnects include:

- Longevity Testing: Rigorous testing under simulated environmental conditions guarantees that microchips can withstand prolonged exposure without significant performance degradation.

- Reliability Assessments: Thorough evaluations help identify potential failure modes, allowing manufacturers to proactively address weaknesses in design and materials.

- Performance Under Stress: Gold’s exceptional conductivity and bonding strength guarantee that microchips maintain peak performance even when subjected to extreme conditions.

Incorporating gold interconnects into microchip designs not only enhances mechanical stability but also extends the overall lifespan of the device. This makes them an indispensable choice for applications where reliability is paramount, ultimately safeguarding the functionality of critical systems in unpredictable environments.

PERFORMANCE IN MINIATURIZATION

The performance of microchips in miniaturization is critically influenced by the properties of gold interconnects, particularly their enhanced electrical conductivity. This superior conductivity facilitates efficient signal transmission in increasingly compact designs. Additionally, the thermal stability and corrosion resistance of gold interconnects contribute to the reliability and longevity of miniaturized components, ensuring peak performance in demanding applications.

Enhanced Electrical Conductivity

Enhanced electrical conductivity is a crucial factor in the performance of microchip manufacturing, particularly as device miniaturization continues to push the boundaries of technology. As devices shrink, the demand for efficient signal transmission increases, making the choice of interconnect materials paramount. Gold interconnects offer superior conductivity, which is necessary for maintaining signal integrity in high frequency applications. This characteristic becomes increasingly important as microchips operate at elevated speeds and reduced dimensions.

The benefits of enhanced electrical conductivity in gold interconnects can be summarized as follows:

- Minimized Signal Loss: Gold’s low resistivity guarantees minimal attenuation of signals, preserving the fidelity of high-frequency transmissions.

- Improved Performance at Scale: As devices become smaller, maintaining high signal integrity allows for more complex functionalities without compromising performance.

- Reliability in Diverse Conditions: Gold’s excellent corrosion resistance guarantees consistent conductivity over time, making it ideal for high-stakes applications.

Thermal Stability Advantages

Thermal stability is a significant aspect of microchip performance, particularly as devices are miniaturized to accommodate increasing demands for speed and efficiency. As microchips shrink, the challenge of managing thermal expansion becomes paramount. Gold interconnects exhibit superior thermal stability, effectively mitigating the adverse effects associated with temperature fluctuations.

When subjected to heat, materials can expand at different rates, leading to mechanical stresses that may compromise chip integrity. Gold’s low coefficient of thermal expansion minimizes these risks, ensuring that interconnects maintain their structural integrity even under varying thermal conditions. Additionally, gold’s excellent thermal conductivity facilitates ideal heat dissipation, essential for preventing overheating in tightly packed microchip architectures.

The ability of gold to dissipate heat efficiently allows microchips to operate at higher speeds without the risk of thermal failure. This characteristic is particularly crucial as manufacturers aim to push the limits of performance in increasingly compact designs. By relying on gold interconnects, microchip manufacturers can achieve the necessary balance between electrical performance and thermal management, ensuring that devices not only meet but exceed the rigorous demands of modern computing environments.

Corrosion Resistance Benefits

Microchip manufacturers face significant challenges as they endeavor to miniaturize components while maintaining performance and reliability. One notable concern is corrosion, which can compromise the integrity of interconnects over time. Gold interconnects provide vital oxidation protection, enabling manufacturers to achieve long-term durability even in compact designs. The unique properties of gold make it an ideal choice for minimizing degradation due to environmental factors. Microchip components are so small they’re measured in nanometers (nm). Some components are now under 10 nm, making it possible to fit billions of components on a single chip.

Key corrosion resistance benefits of gold interconnects include:

- Enhanced Longevity: Gold’s resistance to tarnishing and corrosion guarantees that interconnects maintain their electrical performance throughout the microchip’s lifespan.

- Improved Signal Integrity: The stable surface of gold minimizes contact resistance, which is essential as components shrink and signal pathways narrow.

- Maintenance of Performance Standards: Consistent material properties prevent failures that could arise from corrosion, thereby supporting stringent reliability requirements in miniaturized applications.

Cost Vs. Reliability

In the competitive landscape of semiconductor manufacturing, the balance between cost and reliability remains a critical consideration for engineers and manufacturers alike. The choice of interconnect materials, particularly gold, is a prime example where this balance is meticulously evaluated. A detailed cost analysis demonstrates that while gold interconnects are more expensive upfront, their reliability benefits often justify the investment, especially in high-performance applications.

The reliability assessment of interconnect materials focuses on factors such as thermal conductivity, corrosion resistance, and mechanical stability. Gold’s superior properties in these areas contribute to longer product lifespans and reduced failure rates, ultimately leading to lower total cost of ownership over time. The short-term cost savings of alternative materials can be misleading, as they may lead to increased failure rates and higher maintenance costs.

| Material | Cost per kg | Reliability Rating |

| Gold | $60,000 | 9.8 |

| Copper | $6,000 | 7.0 |

| Aluminum | $2,500 | 6.5 |

As depicted in the table above, the stark contrast in both cost and reliability ratings illustrates the trade-offs involved. Choosing a material for interconnects cannot be a decision made in isolation; it demands a thorough understanding of how cost implications affect long-term reliability. Consequently, the investment in gold interconnects can be seen not merely as an expense, but as a strategic allocation of resources that prioritizes performance and longevity in semiconductor applications.

Future Trends in Interconnects

As the semiconductor industry continues to evolve, the demand for advanced interconnect technologies is intensifying, driven by the need for higher performance and greater miniaturization. In this scenario, future trends in interconnects will be shaped by several key factors, including emerging materials and innovative technologies that address the design challenges posed by shrinking feature sizes.

The industry is witnessing a paradigm shift towards interconnect solutions that can meet growing market demands while also being sustainable. Key trends include:

- Emerging Materials: The exploration of alternative metals, such as copper and silver, is gaining traction as manufacturers seek solutions that can offer comparable performance to gold while reducing costs and environmental impact.

- Innovative Technologies: Techniques such as 3D packaging and advanced lithography are being developed to enhance the integration and density of interconnects, thereby allowing for more compact designs that meet future applications in high-performance computing and mobile devices.

- Sustainable Solutions: The focus on environmentally friendly manufacturing processes is prompting the industry to adopt materials and methods that minimize waste and energy consumption, fostering a more sustainable semiconductor ecosystem.

As these trends unfold, the ability to navigate the complexities of interconnect design and manufacturing will be vital for microchip manufacturers. The future landscape will demand a balance between performance, cost-effectiveness, and sustainability, ensuring that interconnect technologies can keep pace with the rapid advancements in semiconductor applications.

RELATED STUDIES ABOUT GOLD IN MICROCHIP

In the intricate tapestry of microchip manufacturing, gold interconnects emerge as the golden thread, weaving together conductivity, durability, and reliability. Much like a time-honored bridge that withstands the ravages of time and elements, gold’s unique properties guarantee robust performance amidst the relentless march toward miniaturization. While emerging materials may beckon with promises of cost-effectiveness, the steadfast resilience of gold remains an invaluable asset, illuminating the path forward in the quest for innovation in interconnect technology.

Nanomaterials in Microchip Electrophoresis – A Review

Study Overview:

This comprehensive review synthesizes recent advances (since 2010) in the application of nanomaterials (NMs) to enhance the performance of microchip electrophoresis (ME). It highlights how the unique properties of NMs—such as high surface-to-volume ratio, tailored surface chemistry, and multifunctionality—address critical challenges in ME, including improving separation resolution, enabling preconcentration, and facilitating sensitive detection for a wide range of analytes.

Key Findings:

- Role of Nanomaterials in ME Enhancement:

- NMs serve as stationary phases (SP) or pseudostationary phases (PSP) within microchannels, providing additional interaction sites that improve selectivity and resolution for separating complex mixtures (e.g., proteins, DNA, chiral compounds, and small molecules).

- They modify microchannel surfaces (e.g., via layer-by-layer assembly or in-situ synthesis) to control electroosmotic flow (EOF), reduce nonspecific adsorption, and enhance wettability, leading to more reproducible and efficient separations.

- Key Nanomaterial Classes and Applications:

- Gold Nanoparticles (AuNPs): Most widely used due to excellent colloidal stability, ease of functionalization, and biocompatibility. Applications include:

- Improving separation of amino acids, neurotransmitters, and DNA.

- Enabling surface-enhanced Raman spectroscopy (SERS) for sensitive detection.

- Serving as tags or carriers in aptasensors for detecting antibiotics, toxins, and pathogens.

- Magnetic Nanoparticles (MNPs): Offer dual magnetic and nanoscale properties, allowing easy manipulation and reuse. Used for:

- On-chip immunocapture and preconcentration of biomarkers (e.g., β-amyloid peptides).

- Fabrication of tunable chiral stationary phases for enantioseparation.

- Carbon Nanotubes (CNTs): Provide mechanical robustness and high surface area. Used as:

- Stationary phases in microchip electrochromatography (MCEC) for protein and DNA separation.

- Conductive pillars enabling high electric field strengths without bubble formation.

- Silica, Metal Oxide, and Polymer NPs: Used for surface modification, sieving matrices, and as additives to background electrolytes to enhance separation efficiency and stability.

- Preconcentration and Sensitivity Enhancement:

- NMs significantly improve detection limits by enabling on-chip sample preconcentration. Techniques include:

- Field-amplified sample stacking (FASS) and injection (FASI) using AuNP-modified buffers.

- Magnetic bead-based extraction and enrichment of target analytes from complex samples (e.g., food, biological fluids).

- NM-based aptasensors and immunosensors achieve ultra-sensitive detection (down to fM levels) for antibiotics, heavy metals, tumor markers, and bacteria.

- Integration and Multifunctionality:

- NMs facilitate the development of integrated lab-on-a-chip systems that combine sample preparation, separation, and detection.

- Examples include microchips incorporating NM-based enzymatic microreactors, affinity columns, and detection elements (e.g., electrochemical, fluorescence, SERS).

- Future Directions:

- Synthesis of more monodispersed, porous, and selectively functionalized NPs to enhance mass transfer and capacity.

- Design of NPs with highly specific interaction sites for targeted preconcentration and multiplexed detection.

- Development of reusable, stable, and environmentally friendly NM-based ME platforms for point-of-care diagnostics and environmental monitoring.

Conclusion:

The synergy between nanomaterials and microchip electrophoresis represents a rapidly advancing frontier in analytical science. NMs address key limitations of ME—such as short separation lengths, low sensitivity, and matrix interference—by enhancing separation efficiency, enabling sensitive detection, and integrating multiple analytical steps. This review underscores the transformative potential of NM-enhanced ME for applications in pharmaceuticals, clinical diagnostics, food safety, and environmental analysis, pointing toward more portable, efficient, and high-throughput analytical devices.

| REFERENCE: Marija Jozanović, Iva Pukleš, Nikola Sakač, Emanuel Carrilho, Anikó Kilár, Brunislav Matasović, Mirela Samardžić, Mateja Budetić, Ferenc Kilár, Nanomaterials in microchip electrophoresis – A review, TrAC Trends in Analytical Chemistry, Volume 165, 2023, 117111, ISSN 0165-9936, https://doi.org/10.1016/j.trac.2023.117111. (https://www.sciencedirect.com/science/article/pii/S016599362300198X) |

Development And Characterization Of Microchip Electrophoresis Pulsed Amperometric Detector-Based Soil Pesticide Analyser

Objective: To develop a portable, cost-effective, and rapid analytical system for the simultaneous detection of multiple pesticides in soil samples, addressing the limitations of conventional lab-based methods.

Key Findings & Outcomes:

- Device Development:

- A microchip electrophoresis (MCE) device integrated with a pulsed amperometric detector was fabricated.

- An in-house, portable potentiostat controlled by a LabVIEW interface was developed to replace bulky, expensive commercial units.

- Analytical Performance:

- Successfully separated and quantified three pesticides—Chlorpyrifos, Imidacloprid, and Fipronil—from a mixture in 15 minutes using only 2 µL of sample, with no pretreatment or electrode modification required.

- Detection limits (LOD) were:

- Chlorpyrifos: 42.69 µM (14.96 ppm)

- Imidacloprid: 62.61 µM (16.0 ppm)

- Fipronil: 71.14 µM (31.09 ppm)

- Sensitivities ranged from 0.0265 to 0.038 nA/µM across the pesticides.

- Validation with Real Samples:

- The system was tested on soil extracts spiked with known pesticide concentrations.

- Recovery rates averaged 84.3% (±9.4%), confirming reliability in complex soil matrices.

- Advantages Over Existing Methods:

- Eliminates need for extensive sample preparation, toxic chemicals, and centralized lab equipment (e.g., HPLC, GC-MS).

- Provides rapid, on-site detection suitable for field use in agriculture and environmental monitoring.

- Potential for Expansion:

- The platform can be adapted to create a library of detectable compounds using migration time and current response data, similar to chromatographic systems.

Conclusion:

The developed MCE-based sensor system offers a practical, efficient, and scalable solution for on-site pesticide monitoring. It demonstrates significant promise for real-world field applications, enabling timely detection of pesticide residues to support food safety, environmental health, and sustainable agricultural practices.

Implications:

This technology can empower farmers, environmental agencies, and food safety inspectors with a portable tool for rapid pesticide screening, reducing reliance on lab-dependent analyses and facilitating proactive soil management.

| REFERENCE: Rishi Raj, Suddhasatwa Basu, Sandeep Kumar Jha, Development and characterization of microchip electrophoresis pulsed amperometric detector-based soil pesticide analyser, Biosensors and Bioelectronics: X, Volume 19, 2024, 100502, ISSN 2590-1370, https://doi.org/10.1016/j.biosx.2024.100502. (https://www.sciencedirect.com/science/article/pii/S2590137024000669) |

Nanoporous Gold Microelectrode Arrays Using Microchips: A Highly Sensitive and Cost-Effective Platform for Electroanalytical Applications

Study Overview:

This research presents a novel, low-cost electrochemical sensing platform by transforming commercially available surface-mounted device (SMD) microchips into high-performance nanoporous gold microelectrode arrays (NPAu-μE). The work demonstrates that a simple electrochemical treatment can significantly enhance the sensor’s performance for detecting both organic and inorganic analytes, making it suitable for pharmaceutical quality control and environmental monitoring.

Key Findings:

- Sensor Fabrication & Enhancement:

- Gold microelectrode arrays (Au-μE) were fabricated from low-cost SMD microchips by exposing gold microwires through polishing.

- A subsequent electrochemical anodization-reduction process created a nanoporous gold structure (NPAu-μE), increasing the electroactive surface area by approximately 4.4-fold and reducing charge-transfer resistance.

- Improved Analytical Performance:

- The NPAu-μE showed significantly enhanced sensitivity and lower detection limits compared to untreated electrodes.

- Electrochemical impedance spectroscopy (EIS) and scanning electron microscopy (SEM) confirmed the formation of nanoporous structures with increased active sites.

- Applications & Performance Metrics:

- Dipyrone (DIP) Detection: Using batch-injection analysis with amperometric detection (BIA-AD), the sensor achieved a low detection limit (LOD) of 0.57 µmol L⁻¹, a wide linear range (1.0–200.0 µmol L⁻¹), high precision (RSD < 4.0%), and a sample throughput of 148 analyses per hour. Successful application in pharmaceutical samples showed good accuracy and no matrix interference.

- Cysteine (Cys) Detection: Similarly, with BIA-AD, the sensor demonstrated an LOD of 1.2 µmol L⁻¹, a linear range of 5.0–150.0 µmol L⁻¹, and a throughput of 185 analyses per hour.

- Lead(II) Detection: Using square-wave anodic stripping voltammetry (SWASV), the sensor detected Pb²⁺ with an LOD of 2.0 nmol L⁻¹, good linearity across two ranges (24–240 and 289–531 nmol L⁻¹), and excellent recovery (~94%) in spiked drinking water samples at World Health Organization (WHO) guideline levels.

- Advantages Over Existing Sensors:

- The NPAu-μE platform offers comparable or superior performance to many conventional electrodes (e.g., glassy carbon, platinum) but at a significantly lower cost.

- It requires no complex or toxic modifications—only a simple electrochemical pretreatment.

- The disposable nature of the microchips, combined with high reproducibility and fast analysis times, makes the platform ideal for routine and on-site applications.

Conclusion:

The study successfully demonstrates that disposable gold microelectrode arrays, when electrochemically treated to form nanoporous surfaces, serve as a versatile, cost-effective, and high-performance sensing platform. The NPAu-μE sensor is validated for rapid and sensitive detection of pharmaceutical compounds (dipyrone, cysteine) and toxic metals (lead), highlighting its potential for quality control in pharmaceuticals and monitoring of drinking water safety.

| REFERENCE: Gilvana P. Siqueira, Lucas V. de Faria, Raquel G. Rocha, Tiago A. Matias, Eduardo M. Richter, Rodrigo A.A. Muñoz, Iranaldo S. da Silva, Luiza M.F. Dantas, Nanoporous gold microelectrode arrays using microchips: A highly sensitive and cost-effective platform for electroanalytical applications, Journal of Electroanalytical Chemistry, Volume 925, 2022, 116880, ISSN 1572-6657, https://doi.org/10.1016/j.jelechem.2022.116880. (https://www.sciencedirect.com/science/article/pii/S1572665722008724) |